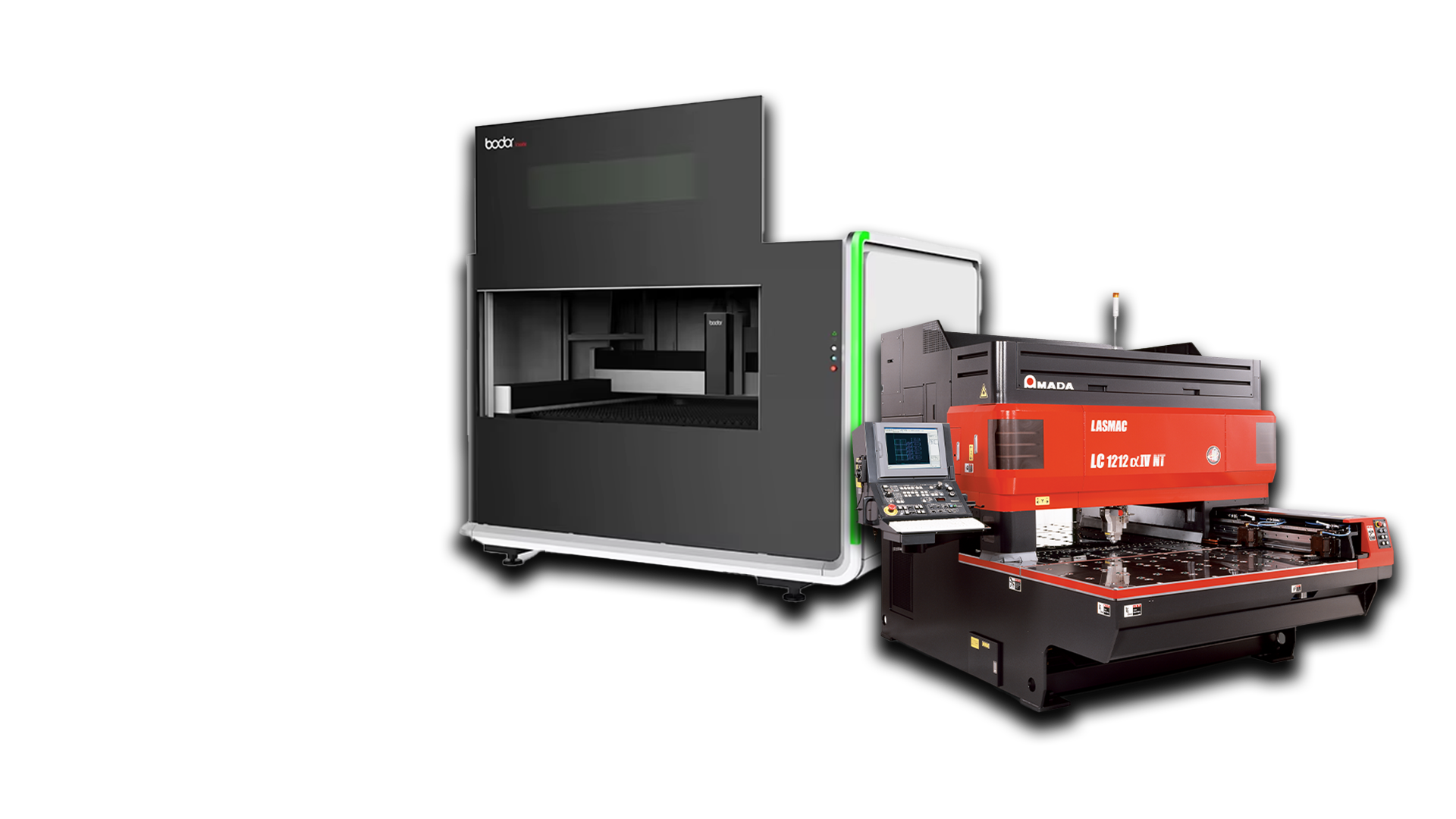

Laser Machines

Laser, Plasma, and Water Cutting machines deliver high-precision cutting and shaping for metals and other materials, using advanced energy-based technology.

Laser Machines

Laser machines are precision cutting and processing systems that use concentrated laser energy to cut, engrave, weld, or mark metal and other materials. In metal fabrication, laser cutting machines are commonly used for high-accuracy cutting of sheet metal, plate, and tubing with minimal material waste and excellent edge quality. Laser machines include fiber lasers, CO₂ lasers, tube lasers, and combination laser systems designed for both cutting and forming applications.

Common laser machine manufacturers include Trumpf, Bystronic, Amada, Mazak, Mitsubishi, Prima Power, Salvagnini, and Han’s Laser. Browse our current inventory of laser machines for sale below.

All Machines (0)

0 Machine(s) Selected

Laser Machines

Laser machines have become a core technology in modern metal fabrication due to their speed, accuracy, and versatility. By using focused laser beams, these machines can cut complex shapes with tight tolerances while producing clean edges that often require little to no secondary finishing.

Laser machines are widely used in industries such as aerospace, automotive, electronics, energy, medical, and general fabrication. Their ability to process a wide range of materials—including steel, stainless steel, aluminum, brass, and copper—makes them an essential part of high-throughput fabrication environments.

How Laser Machines Work

Laser cutting machines generate a high-powered laser beam that is focused through optics onto the material surface. The concentrated energy melts, burns, or vaporizes the material, while assist gases such as nitrogen or oxygen help eject molten material from the cut.

Modern CNC-controlled laser machines allow for precise control of cutting paths, speeds, and power levels, enabling consistent and repeatable results across both simple and complex part geometries.

Types of Laser Machines

Laser machines are available in several configurations, each designed for specific applications:

Fiber Laser Cutting Machines

Fiber lasers are the most common type of laser machine used in metal fabrication today. They offer high cutting speeds, low maintenance requirements, and excellent efficiency, especially for thin to medium-thickness metals.

CO₂ Laser Cutting Machines

CO₂ lasers are well suited for cutting thicker materials and non-metallic materials. While less common in new installations, used CO₂ laser machines remain popular due to their versatility and lower acquisition cost.

Tube and Pipe Laser Machines

Tube lasers are designed to cut round, square, and structural tubing with high precision. These machines are widely used in furniture manufacturing, automotive components, and structural fabrication.

Combination Laser Machines

Combination laser systems integrate laser cutting with punching or forming capabilities, allowing multiple operations to be completed in a single setup.

Benefits of Laser Machines

Laser machines offer several advantages over traditional cutting methods:

- High cutting accuracy and repeatability

- Minimal material waste

- Clean edges with reduced secondary processing

- Fast setup and changeover times

- Ability to cut complex geometries

- Compatibility with automation and material handling systems

- These benefits make laser machines ideal for both high-mix and high-volume production environments.

Laser Machines vs Plasma and Waterjet Cutting

Compared to plasma cutting, laser machines provide finer detail, tighter tolerances, and superior edge quality. While waterjet cutting excels at thick materials and heat-sensitive applications, laser cutting offers faster cycle times and lower operating costs for many sheet metal applications.

Many fabrication shops use laser machines alongside plasma and waterjet systems to cover a wide range of cutting needs.

Automation and Material Handling

Modern laser machines are often integrated with automation systems such as pallet changers, tower storage systems, robotic loading, and part sorting solutions. These systems increase throughput, reduce labor requirements, and enable lights-out operation for maximum productivity.

Buying a Used Laser Machine

Purchasing a used laser machine can significantly reduce capital investment while still delivering high-performance cutting capabilities. When evaluating a used laser machine, consider:

- Laser source type and power level

- Cutting bed size and material thickness capacity

- Control system and software compatibility

- Maintenance history and operating hours

- Availability of replacement parts and service support

- Electrical and facility requirements

Comparing similar models—such as used Trumpf fiber lasers, Bystronic laser cutters, or Amada laser machines—can help ensure you select the right system for your operation.

We’re Here to Help

Our team specializes in sourcing high-quality used laser machines from manufacturers across the U.S. Whether you’re adding your first laser cutter or upgrading to a higher-powered system, our experts can help you find the right laser machine for your production needs. Contact us today to learn more about current inventory and upcoming laser machines.

Looking for a Specific Model?

Looking for a specific machine model? Our network can quickly source any make, model, or configuration to align with your production needs and budget.